PROCESS

Inovation

More Than 50 Years Of Innovation. Our reputation for product excellence is based upon true innovation in product design. We are constantly making improvements to our product line to incorporate features and benefits that make Leaktite products the best and most trusted products in the market.

Our Polysteel bucket is full of features that are designed to stand up to the toughest use. Its spring steel inner ring eliminates distortion when carrying. Steel handles connect to the inner ring to support the bucket and the handle can stay in an upright position. The pliable plastic sides makes the removal of dried paint quick and easy.

Our wallpaper trays are just another example of how we design products for the real world. Tray handles are molded right in for comfort in carrying and handling of trays that are full. Plus, our trays are ribbed for extra strength and stability.

We just made the 3 1/2 and 5 gallon pail lid even better. Our #6 GLD flexible Easy-Off lid opens by hand …no more prying with tools! The Easy-Off lid makes opening and re-sealing easier than ever before.

The 3 1/2 and 5 gallon gasket lid makes a super tight “leak-tight” seal on the pail with its inner rubber gasket.

Leaktite’s line of American-made 5-quart metal pails are the finest metal pails available on the market today. Double ribbed, rolled metal edges and lock seam construction assure the most long lasting and durable metal pails that will stand up to the toughest use.

Leaktite offers custom offset printing of our line of plastic pails and buckets. With printing up to four colors, you can design a look that is perfect for promotional programs that require a custom look. An excellent way to bring your private label product to market.

Manufacturing

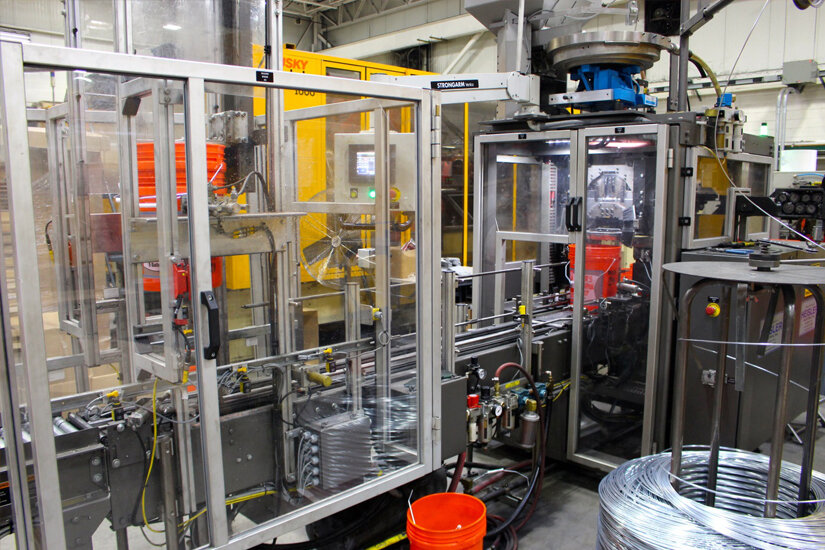

Sound manufacturing techniques, smart raw material management, and skilled labor allows Leaktite to be competitive in the many markets we serve.

Our metal forming, injection molding and thermoforming equipment has kept pace with the changing technology of plastics manufacturing in order to provide the benefits of the latest in manufacturing techniques to it’s customers.

Our 400 ton to 1100 ton injection molding presses keep Leaktite competitive by minimizing cycle times and providing a cost effective manufacturing platform for larger items such as our five gallon bucket.

Our experience in metal forming pails, since 1945, means that our metal products are among the best quality produced in the world. Subtle design and manufacturing advancements in our basic line of metal pails have proved to increase customer satisfaction and durability of the products over the years.

Our in-line thermoforming machinery is capable of running various gauges of materials to suit the many applications of our product line. As with injection molding, die, mold design and construction are critical to quality products. Leaktite’s control procedures over the construction and maintenance of it's dies and molds assure for the manufacture of the highest quality products time after time.

Leaktite implements quality assurance programs consistent with both specific customer requirements and industry standards that meet or exceed our customer's expectations.

Leaktite strictly adheres to OSHA regulations within our manufacturing facilities to provide a safe and healthy working environment for our employees.

Available in Packs of 50 or in a 5-piece set (10 sets per case)

This 5 Qt. Plastic Pail Liner will help make cleaning up on your next painting job a breeze.

The solvent-resistant plastic liner fits a #5 metal pail.

15mil thickness

The liner is ideal for any small painting job.

View Product Specification Sheet

Item Number: 1045061 (Packs of 50)

Item Number: 1044575 (10 Sets of 5)

UPC: 084305350558 (Packs of 50)

UPC: 084305392688 (10 sets of 5)